TABLE OF CONTENTS

Labor shortages and rising operational costs are increasingly pushing manufacturers to automate faster than ever. As a result, the industrial automation market is projected to grow from $238.13 billion in 2025 to $449.77 billion by 2032.

Artificial intelligence (AI) in industrial automation plays a central role in this growth, enabling more adaptive systems that optimize processes, increase throughput, and support better decision-making across the factory floor.

Industrial automation is reshaping what’s possible in manufacturing, logistics, agriculture, and beyond. The companies leading this shift are helping teams work more efficiently, improve precision, and reduce reliance on manual labor.

Artificial Intelligence in Industrial Automation

Integrating artificial intelligence in industrial automation is what defines the most advanced tools on the market today. AI enables robots to learn from operators, inspect parts in real time, and make split-second decisions that improve safety and output.

As AI becomes more deeply embedded in everything from computer vision to generative algorithms, companies can scale faster, reduce waste, and unlock new levels of flexibility in manufacturing and delivering products.

Let’s look at how today’s industrial automation companies use AI and innovative technologies to build faster and superior products.

Mirka

Mirka is best known for sanding and surface finishing tools, but they’ve now taken that expertise into automation. Through the acquisition of Flexmill, they’re building robotic polishing systems that improve consistency and reduce manual labor in manufacturing and aerospace settings. Mirka recently announced its first production site outside of Europe, in Indianapolis, to strengthen its presence in the U.S. market and better support its growing customer base.

Dodge Industrial

Dodge Industrial makes the hardware that keeps production lines moving, such as bearings, gearboxes, motors, and mechanical drives. Their products are everywhere behind the scenes, helping factories and facilities run smoothly and safely. Dodge Industrial also offers an intelligent condition monitoring platform called OPTIFY that combines its Industrial Internet of Things (IIoT) and data analytics to reduce machine downtime.

Augury

Augury combines sensors and machine learning to help companies predict when machines are about to fail before they do. The Augury platform listens to equipment, spots issues early, and cuts down on surprise downtime, helping manufacturers avoid costly delays. Augury has seen its revenue increase fivefold in the past three years, and recently raised $75 million in a Series F round.

Blue River Technology

Blue River Technology, by John Deere, builds smart agricultural equipment that uses cameras and machine-learning systems to spot and target only the weeds. This saves chemicals, reduces waste, and gives farmers better control in the field. It’s automation with a real-world sustainability impact. Blue River Technology allows farmers to reduce the amount of herbicides sprayed by 90%.

inVia Robotics

inVia Robotics builds autonomous robots that help warehouses pick and move products. The inVia robots pair with AI-powered software to optimize inventory flow and boost efficiency in e-commerce and logistics—no infrastructure overhaul needed. In 2024, inVia Robotics was named the “Top Supply Chain Project” for its role in transforming Scholastic Canada’s fulfillment operations through intelligent automation.

Rugged Robotics

Rugged Robotics is automating one of construction’s most repetitive tasks: layout marking. Rugged Robotics makes robots that draw precise layout lines directly onto job site floors, so what used to take a team hours with tape measures and chalk now takes minutes, with pinpoint accuracy. This saves time, reduces human error, and addresses a growing workforce shortage in construction.

Durin

Durin, a startup based in El Segundo, is developing autonomous drill rigs for mineral exploration. In early 2025, Durin raised $3.4 million in pre-seed funding, led by 8090 Industries, and they are now planning field testing in Nevada. Mining may be ancient, but Durin’s approach is anything but.

Saronic Technologies

Saronic Technologies is reimagining maritime operations with autonomous surface vessels. Saronic Technologies has two flagship vehicles—Mirage and Cipher—which are built for long-range missions, carrying significant payloads and operating with minimal human oversight. The goal: safer, smarter ocean operations. Last year, Saronic raised $175 million in Series B funding, which placed its valuation at $1 billion.

Lumafield

Lumafield is moving industrial CT scanning from the lab to the factory floor, giving manufacturers a fast, nondestructive way to inspect internal part geometry. Combined with AI-powered software, the Lumafield Neptune and Triton scanners help teams catch hidden defects, validate assemblies, and reduce failure rates—all without slowing production. From EVs to medical devices, Lumafield is making advanced inspection accessible to a broader range of industries.

Standard Bots

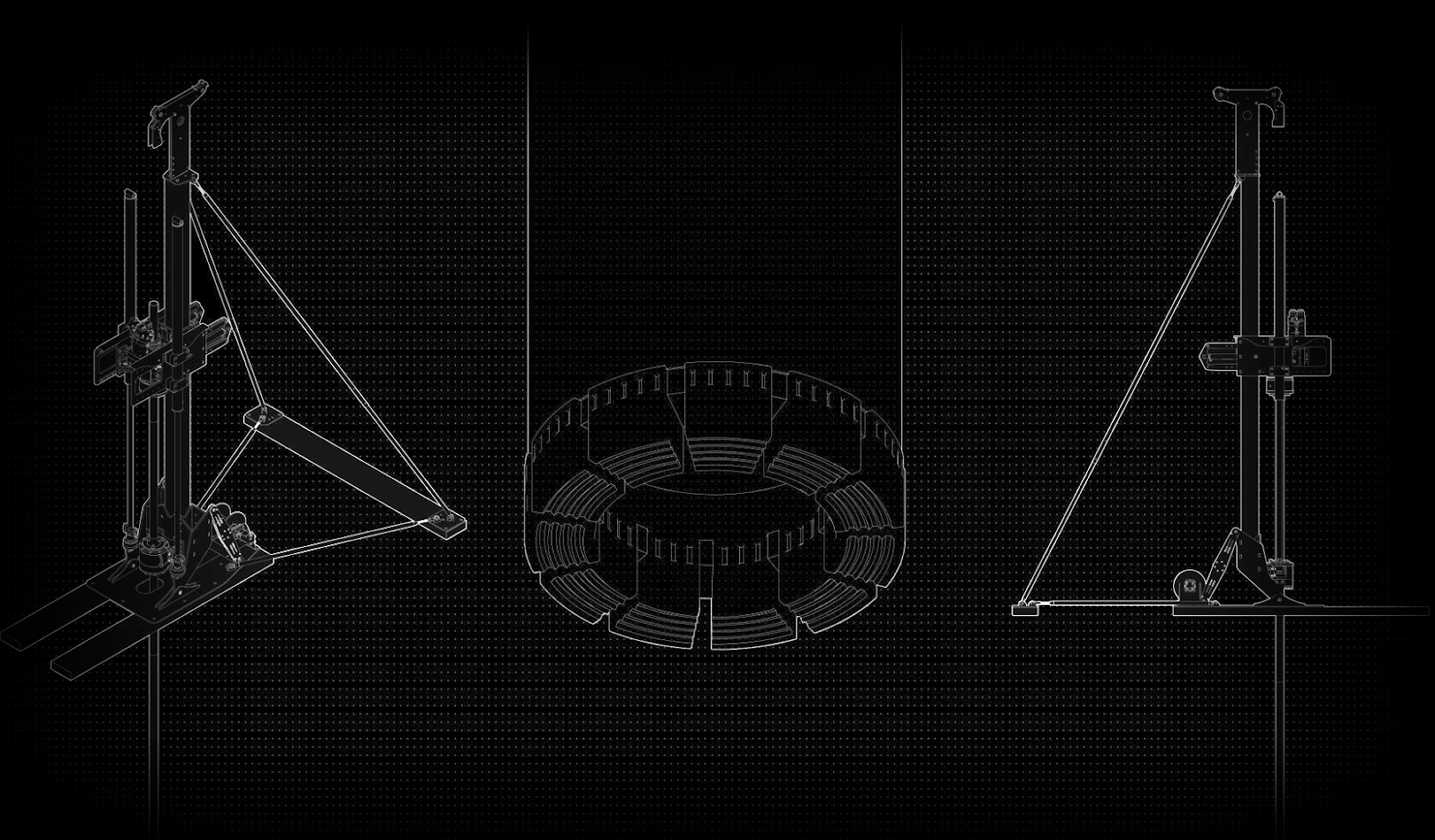

Standard Bots is building AI-powered industrial robot arms that are fast, adaptable, and easy to deploy, bringing next-generation automation to manufacturers of all sizes. Standard Bots’ RO1 robot combines advanced six-axis hardware with intuitive software that allows operators to set up and train tasks in minutes, no coding required. With a growing library of use cases—from machine tending to palletizing, Standard Bots is helping factories boost productivity, reduce repetitive strain on workers, and unlock new levels of flexibility through AI.

What’s Next for Industrial Automation?

Automation isn’t just about replacing tasks; it’s about building adaptive systems that learn, improve, and scale. The rise of artificial intelligence in industrial automation is pushing companies across sectors, from agriculture to aerospace and robotics, to rethink how they design, build, and operate.

To keep up, industrial automation companies are turning to AI-powered PLM software that enables faster iteration, real-time collaboration, and smarter change management. The right tools support innovation in an industry where timing and precision matter.

Duro Design, the first AI-native PLM, was built for this new era of industrial automation. With features like natural language search, automated part numbering, and built-in revision control, Duro helps hardware and engineering teams move faster without sacrificing traceability or quality.