TABLE OF CONTENTS

The use of AI in supply chain is becoming essential as the global supply chain is now a complex, interconnected network where even small disruptions can trigger significant delays or shortages. Ongoing tariffs, shifting trade policies, and geopolitical tensions add pressure, driving companies to adopt AI to predict disruptions, optimize logistics, and adapt quickly.

This change is happening fast, with 95% of data-driven decisions expected to be partially automated. AI is becoming a standard tool for hardware and manufacturing companies looking to anticipate potential disruptions, optimize logistics networks, and respond to unforeseen events with agility.

This article examines how AI in supply chain is reshaping operations and how manufacturers can use AI-powered systems, such as generative AI and predictive analytics, to optimize production, BOM management, streamline change orders, improve logistics, and build more resilient networks.

How AI works in the Supply Chain

In the global supply chain, companies must take a proactive and integrated approach to thrive in a competitive market. Supply chains now play a central role in achieving broader business goals like cost efficiency, competitive differentiation, and customer satisfaction.

Using AI systems to process supply chain data allows companies to optimize operations, improve supply chain visibility, and strengthen supply chain risk management. AI can process vast amounts of information and continuously improve its ability to detect patterns and predict outcomes, helping to identify inefficiencies, mitigate risks, and recommend solutions.

AI can analyze logistics data to anticipate delays—such as port closures or weather events—and recommend alternate shipping routes to ensure on-time deliveries. It can also help companies quickly identify alternative suppliers by analyzing supplier financial health, customer ratings, sustainability metrics, and real-time news alerts.

In some cases, AI is even being used to negotiate with suppliers, reducing the resources needed for vendor communication.

How Does AI affect Supply Chain Performance?

AI helps manufacturing companies streamline operations and tackle challenges more efficiently. Generative AI, in particular, enables them to model possible supply chain issues before they occur. AI analyzes data to predict disruptions, accurately forecast demand, adjust production schedules, and monitor equipment performance.

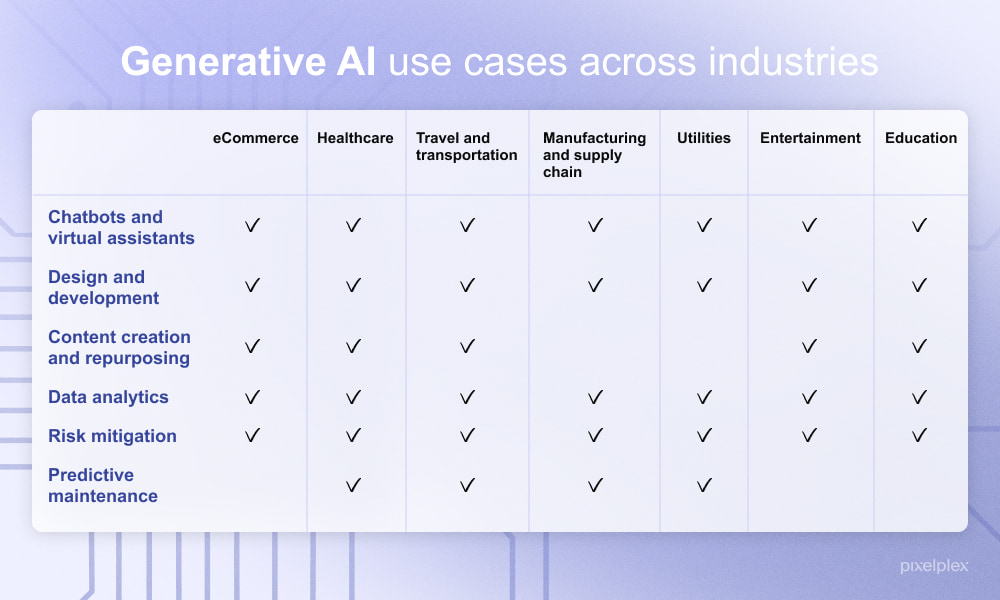

Generative AI in the supply chain

Generative AI reshapes supply chain management by enabling companies to simulate complex scenarios, identify risks, and test strategies before implementation. Manufacturers can model the impact of supplier shutdowns or material shortages and develop contingency plans in advance.

GenAI makes decision-making faster and more informed by turning large data sets into actionable insights. Whether suggesting optimal inventory levels or identifying backup suppliers, GenAI enables businesses to remain agile in the face of uncertainty. As it advances, its role in supply chain optimization will continue to grow.

Mitigating Disruptions with AI

AI can predict supplier delays or extreme weather by analyzing real-time and historical data and recommend contingency plans. AI in procurement helps identify alternative suppliers, optimize purchasing decisions, and ensure the timely delivery of materials.

With AI, manufacturers can anticipate raw material delays or factory shutdowns and adjust sourcing or production schedules. Certain AI-powered models can analyze weather patterns or logistical bottlenecks to recommend alternate sourcing options, minimizing the operational impact.

Demand Forecasting and Planning

Enhanced demand forecasting lets manufacturers align production with relevant market needs. Top robotics companies use AI to analyze order trends, component availability, and production capacity to meet demand without overproducing or facing shortages.

Logistics Optimization in Manufacturing

AI can monitor production processes and equipment health, identify potential issues, and alert teams before breakdowns occur. AI-powered predictive maintenance tracks machinery performance and schedules repairs before costly downtime occurs.

Predictive analytics helps minimize unexpected expenses by identifying bottlenecks early. This alerts teams when a part will run out of stock, preventing costly rush shipments or unscheduled production stops.

AI in Supply Chain Examples

Supply chain workflows

Robotics companies use AI to streamline workflows by automating repetitive manufacturing tasks. By integrating AI with production lines, they eliminate bottlenecks caused by manual intervention, enabling faster production timelines and more reliable delivery schedules for their customers. Rapid Robotics uses a supply chain solution powered by Gen AI and 3D vision.

Smart warehouses

E-commerce platforms use AI to anticipate shopping trends and adjust inventory levels, ensuring their supply chains remain responsive and well-stocked. By leveraging these insights, manufacturers and suppliers can effectively align their operations to meet consumer demand.

Retail forecasting

AI-powered robots handle picking, packing, and sorting tasks with unmatched accuracy and speed, cutting down on human error and labor costs. AI ensures supply chain efficiency by accelerating order fulfillment times and reducing errors that could delay shipments. This capability enables manufacturers and distributors to meet customer demand better while optimizing their supply chain operations.

Shipping logistics

Shipping companies are employing AI to navigate severe weather and other local disruptions. AI monitors weather patterns, dynamically reassigns delivery vehicles, and forecasts issues such as road closures, thereby maintaining delivery schedules.

Smarter PLM Can Now Manage Your Supply Chain

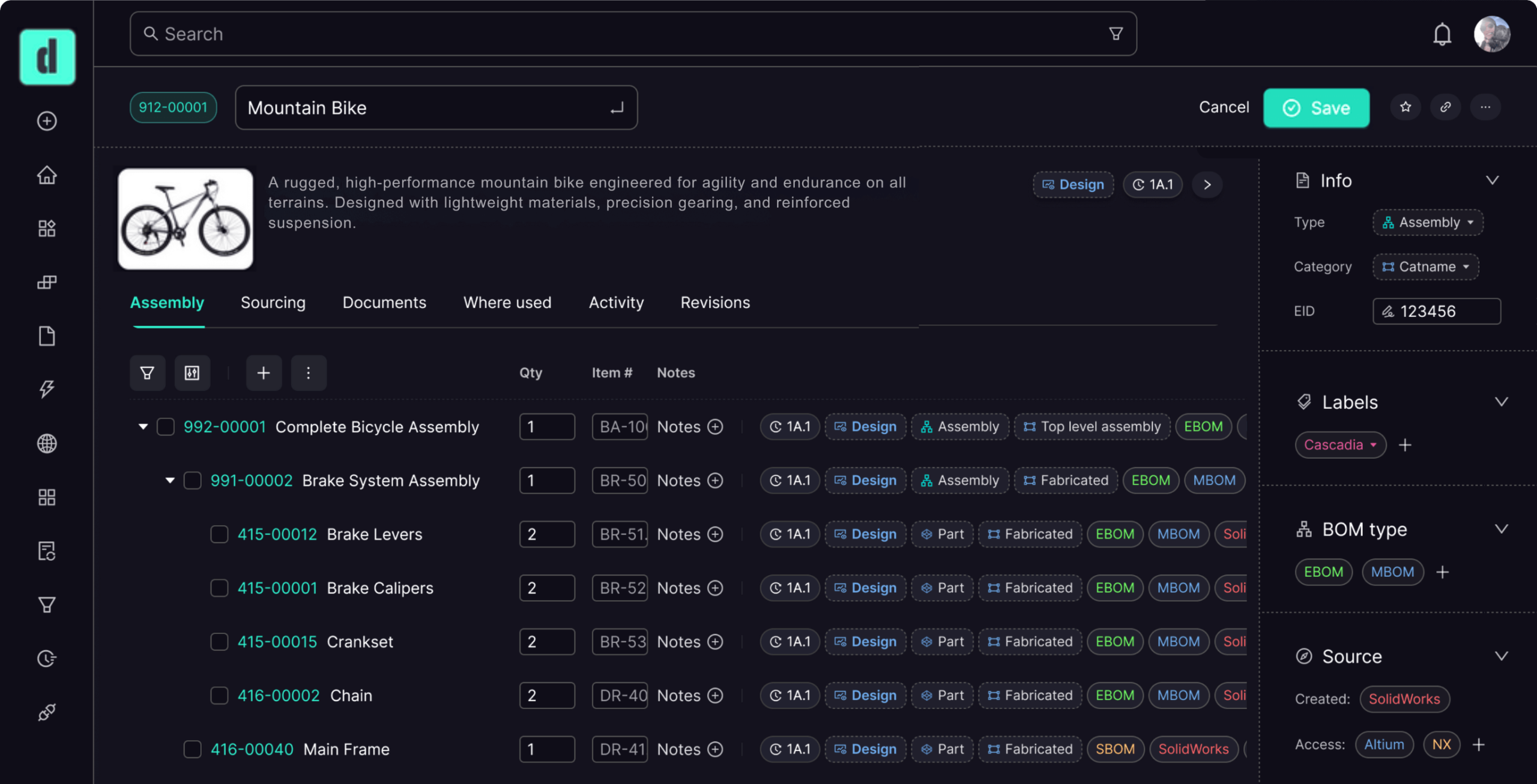

AI-native PLM platforms are becoming the backbone of the digital supply chain, providing the digital thread that connects design, sourcing, manufacturing, and delivery in one unified system.

By integrating AI with BOM management, engineering change orders, and supplier data, PLM systems ensure every change—whether a design update or a sourcing adjustment—flows instantly to all relevant stakeholders. This reduces miscommunication, shortens response times, and improves overall supply chain visibility.

When paired with natural language search, it’s even easier for supply chain and engineering teams to find the exact parts, revisions, or supplier records they need—without having to dig through filters or static fields. This means faster decisions, fewer delays, and a single, connected view of product and supply chain data

Lumafield used PLM to replace manual revision tracking and scattered sourcing data with a single source of truth. Their supply chain team can now access drawings, part numbers, and supplier information instantly—reducing quoting times, avoiding errors, and keeping production on schedule.

This level of integration ensures that disruptions are addressed faster, inventory is optimized, and production stays on track, creating a stronger, more agile supply chain.

The Future AI in Supply Chain

AI in supply chain management provides manufacturers with enhanced agility, visibility, and efficiency. Predictive analytics and generative AI will continue strengthening the digital supply chain, helping companies avoid both. I have a lot of calls today, so give me a shout tomorrow. Anticipate and adapt to change faster than ever.

For industries like aerospace, robotics, and industrial automation, where delays can cost millions, AI-native PLM software acts as the true digital thread, ensuring all product and supply chain data stays connected from concept to delivery.

By leveraging AI in PLM, companies gain real-time visibility, improve collaboration, and future-proof their operations against market volatility, tariff changes, and material shortages—building a supply chain that’s resilient, adaptable, and ready for what’s next.