TABLE OF CONTENTS

Every delay has a ripple effect in hardware design and manufacturing. A change order stuck in approval wastes time, and can derail production schedules, disrupt supplier contracts, and lead to expensive rework. The pressure mounts as hardware development moves faster and supply chains grow more complex.

We see how tariff changes can make a preferred component unavailable overnight. A single sourcing issue can stall multiple assemblies. And with product lifecycles shortening, companies can’t afford to wait days or weeks for an engineering change to move forward.

For engineering teams building satellites, electronic vehicles, or consumer electronics, fast approvals can be the difference between hitting a launch window or missing it entirely. Here, we will show you how to do this in seconds.

What Is a Change Order?

A change order, often called an ECO (Engineering Change Order), is the formal process for updating product information, whether it’s a design revision, part replacement, or sourcing adjustment.

A single change might seem straightforward, but its effects can be far-reaching. An updated CAD model triggers drawing revisions and tolerance checks. A switch to a new supplier forces sourcing teams to renegotiate lead times and pricing. Even compliance teams need to update documentation to meet regulatory standards.

When managed well, change orders keep teams aligned and products accurate. But when they’re delayed or handled manually, one overlooked dependency can snowball into production errors and supply chain slowdowns.

Why Traditional Change Management Lags

Despite their critical nature, change orders are still managed with outdated methods in most hardware organizations. Email chains track approvals, PDFs pass between teams with no clear version history, and key decisions rely on knowledge confined to a few people’s heads.

This lack of structure creates blind spots. Teams can’t instantly see which assemblies or suppliers a change affects, so they spend hours manually tracing relationships before signing off. When decisions take days to move through fragmented approval chains, the result is stalled production and missed deadlines.

A clear, standardized change order checklist ensures every step, from verifying supplier impact to confirming updated documentation, happens in the right order. But even with a solid checklist, traditional tools slow teams down. AI-native PLM changes that by making these checks automatic and instantaneous.

How AI-Native PLM Does the Opposite

AI-driven PLM removes slow, manual steps that bog down traditional systems. Instead of filling out fields by hand, engineers get automatic validation and error checking, reducing back-and-forth corrections. Natural language search replaces endless filter clicks, letting someone ask, “Which assemblies will be delayed if this part is replaced?” and get an immediate answer.

Impact analysis is instant. Costs, affected suppliers, and lead times update in real time, giving teams the confidence to approve changes without spending hours gathering context. A robotics company switching to a new motor supplier could see, before approving the change, which assemblies need new torque testing and whether the lead time shift would affect its production schedule.

Instant Approvals and Automation

The real shift comes when approvals aren’t just faster but automatic. Modern PLM platforms route change orders to the right people based on predefined rules, removing the usual bottlenecks.

Visual diffs make it easy to spot exactly what’s changed in a bill of materials (BOM), CAD file, or document. With GitHub-style change tracking, every revision is logged and traceable, eliminating confusion about who approved what and why.

With the right PLM, the engineering team at AstroForge was able to process last-minute design updates without delaying production, allowing them to build a space mining vehicle in just twelve months.

Approve Your Change Orders in Seconds

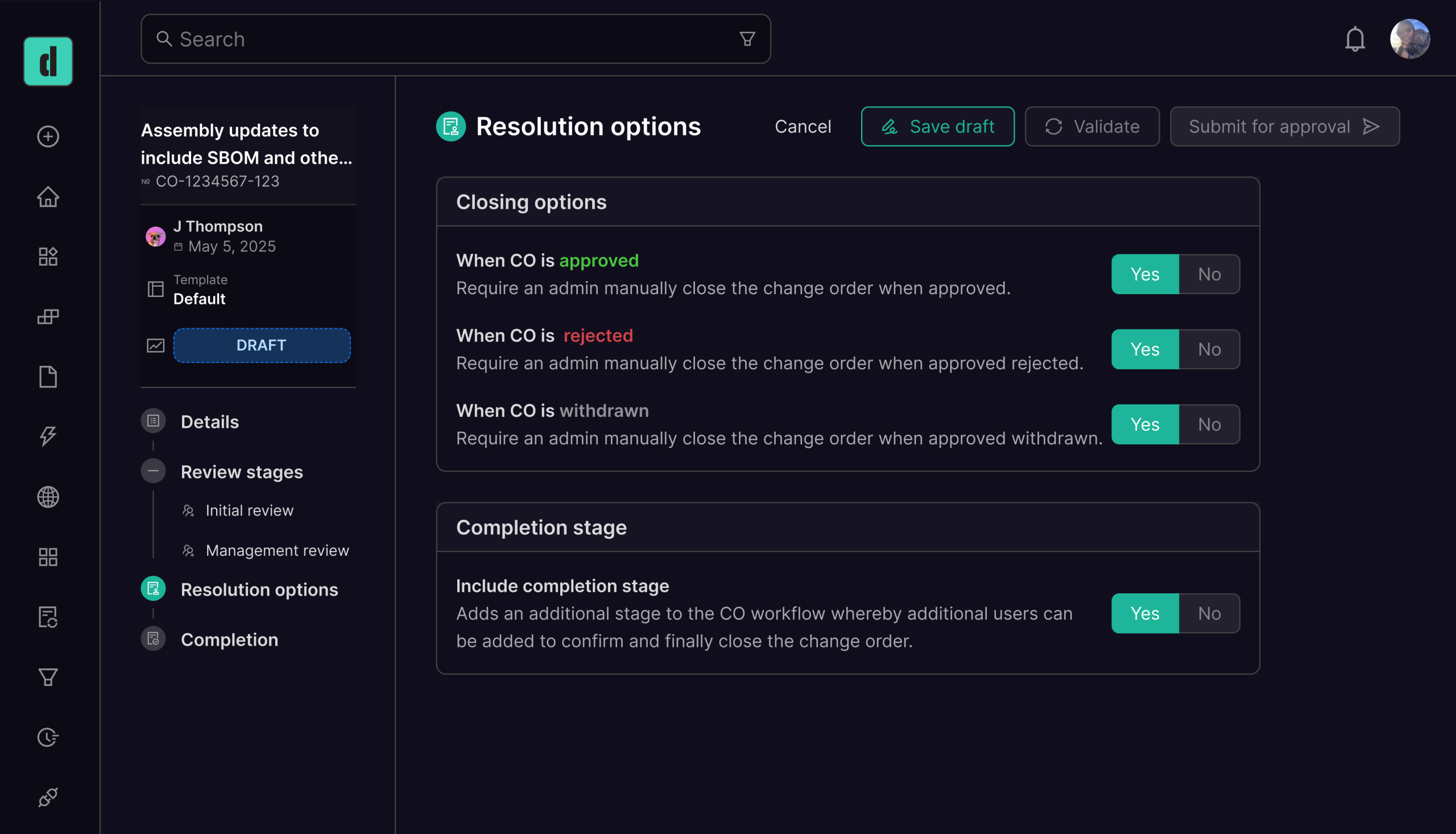

Duro Design, a newly rebuilt AI-native PLM platform, was designed specifically for hardware teams that need to move quickly without sacrificing accuracy. Simple BOM management, natural language validation, configurable workflows, and centralized impact data mean approvals that once took days can now happen in seconds, with every decision fully documented for traceability.

The flexibility of Duro Design’s change management workflows is a big part of that speed. Teams can define exactly who needs to approve what, whether it’s a quick sign-off for a minor part swap or a multi-step review for a critical design change. Those rules run automatically in the background, routing change orders to the right people without bottlenecks or unnecessary sign-offs.

Engineers don’t have to wrestle with complicated filters or wait on admins for reports, because the system surfaces the correct information automatically. Operations teams can see the full impact of a change before approving it, cutting down on second-guessing and expensive surprises.

Duro Design is the first AI-driven PLM built for fast, reliable change management. When approvals can be made in seconds, with the context that teams need to make the right decisions every time, manufacturers can keep production on schedule while the engineering team focuses on building what’s next.