TABLE OF CONTENTS

Nearly 25% of procurement budgets are now being directed toward digital tools and AI. Tariffs, shortages, and volatile supplier markets put constant pressure on manufacturers. Procurement is no longer a back-office function—it’s becoming digital, embedded in design, and essential for competitiveness.

The future of procurement is already here: supplier choices are made during the design stage, not after. This article defines digital procurement, explores why the engineering-procurement gap continues to create delays, and shows how PLM software enables smarter, faster sourcing strategies.

What Is Digital Procurement?

Digital procurement replaces manual, transactional purchasing with connected, data-driven systems. These platforms give teams visibility into suppliers, pricing, and compliance, so decisions are based on current information, not outdated spreadsheets.

What this looks like day-to-day is supplier data showing up inside the design tools engineers already use. If a part shows a 40-week lead time, the team can pivot to another option available in three weeks and avoid the kind of surprise that can stall production.

A strong digital procurement strategy brings these decisions forward in the product lifecycle. Looking at supplier capacity, cost, and compliance during the design stage helps teams catch problems before they snowball into delays. This is where PLM comes in – by bringing that information into the process early, procurement and engineering stay in step.

PLM Software Explained

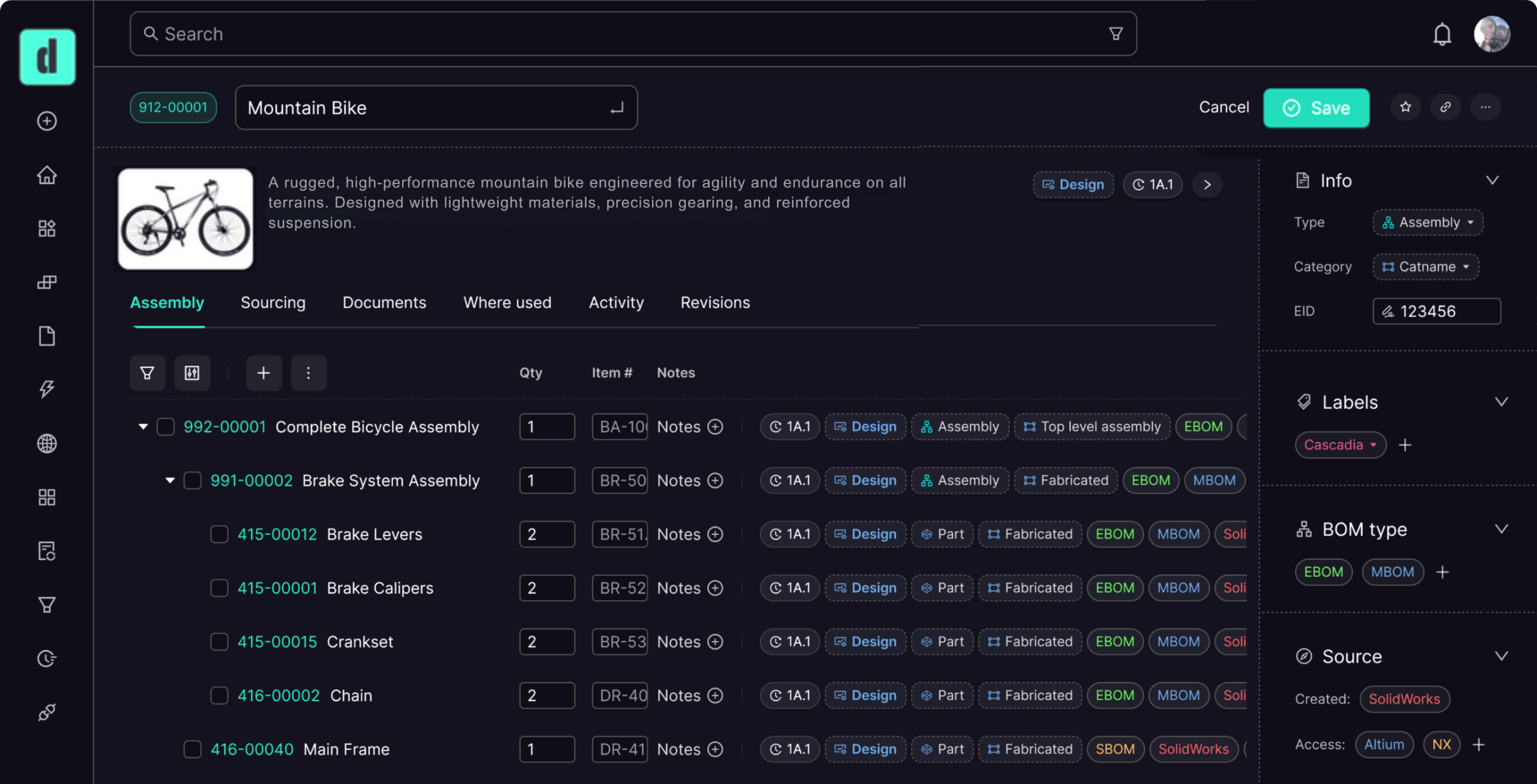

PLM (Product Lifecycle Management) software manages the data, revisions, and workflows behind every product. It keeps bills of materials (BOMs) accurate, tracks every design change, and connects engineering with the rest of the business.

ERP systems focus on finance and manufacturing resources, while PDM systems handle file control. PLM software complements both by linking design intent to procurement and production realities, making it the foundation of digital procurement.

With PLM in place:

- BOM management is centralized and accurate

- Supplier data is linked to design decisions

- Procurement teams can see how engineering changes affect sourcing in real time

With integrations to CAD tools like SolidWorks and Altium 365, PLM can surface information about component availability, approved suppliers, and compliance requirements directly inside the design workflow.

Engineers get context they can act on immediately, and procurement gains confidence that every part selected is both manufacturable and sourceable.

The Gap Between Engineering and Procurement

In many organizations, engineers work in CAD and PLM while procurement operates in ERP or standalone sourcing tools. This disconnect creates mismatched BOMs, outdated part specifications, and costly delays.

When procurement teams don’t see design changes until after they’ve been released, they are forced to react instead of plan. A part may be swapped out in engineering, but procurement doesn’t see the change until the BOM reaches ERP. By then, orders may already be placed or suppliers lined up for the wrong component.

Working this way raises supply chain risk, drives up expenses, and makes it harder to maintain strong supplier ties. PLM addresses the problem by making sure everyone sees the same product record, so procurement and engineering stay aligned.

Smarter Digital Procurement Strategy

With product lifecycle management, procurement doesn’t have to wait for final drawings or frozen BOMs. They can see engineering updates as they happen and make sourcing decisions with current data.

- Accurate BOMs mean procurement sources from the right specifications every time, cutting down on duplicate orders and mismatched parts.

- Supplier information tied to design data reduces back-and-forth, speeds up purchasing, and helps both sides stay on the same page.

- Change tracking in real time ensures a new part number or a spec update doesn’t catch procurement off guard.

- A digital thread connects design decisions to sourcing, so every purchase order is backed by context.

The result is procurement that’s faster, more resilient, and able to anticipate risks instead of reacting to them.

Benefits of PLM-Driven Digital Procurement

When procurement runs through PLM, procurement shifts from a reactive function to a proactive one. Teams can expect measurable improvements across cost, speed, risk, and supplier collaboration.

- Lower sourcing costs – Errors like ordering the wrong part or duplicating purchases get caught early, which reduces scrap, rework, and last-minute expediting fees. Over time, this translates into real savings across the supply chain.

- Faster cycles – Because procurement has visibility into design updates the moment they happen, purchasing decisions can move forward without waiting for final release packages. That cuts lead times and keeps production schedules intact.

- Reduced risk – When procurement sees design changes or supplier issues early, they can make adjustments before problems grow. That might mean switching suppliers ahead of a shortage, balancing inventory levels, or re-quoting parts before costs spike.

- Stronger supplier relationships – Clear, accurate data helps suppliers plan with confidence. That reliability often leads to better pricing, stronger support, and longer-term partnerships.

A PLM Built for Digital Procurement

Procurement has become a lever for competitiveness. With volatile supply chains, long lead times, and complex compliance requirements, sourcing decisions must be made alongside engineering rather than after the fact. Your PLM should play a central role here by giving teams the visibility and control needed for effective supply chain risk management.

The right PLM should act as the central record for product data, bridging the gap between engineering decisions and procurement needs. When designs change, the updates carry through immediately, keeping BOMs current and giving suppliers a clear view of what’s ahead. This alignment helps procurement move faster and with fewer errors.

Duro PLM was designed and built for this new procurement model. With direct CAD integrations, live change tracking, and configurable workflows, it keeps sourcing tied to engineering in real time. That true digital thread helps manufacturers cut costs, move faster, and build supply chains that can handle uncertainty.