TABLE OF CONTENTS

The importance of supply chain risk management has never been higher, with economic and geopolitical pressures driving uncertainty across industries. Manufacturers from startups to global enterprises are prioritizing strategies to anticipate, identify, and mitigate disruptions before they escalate.

Supply chain challenges are nothing new. In 2024, nine in ten manufacturers reported significant delays in production and sourcing, with some even taking their foot off the gas. We are seeing a clear shift now, with companies now doubling down on resilience planning.

This article examines the current state of the global supply chain, the most pressing risks, and how building a true digital supply chain connects design, sourcing, and production to help manufacturers respond faster and maintain stability.

The Current Global Supply Chain

Geopolitical tensions, trade disputes, and material shortages are straining the global supply chain. Tariffs as high as 30% on Chinese goods and 10–25% on imports from other countries have made production more expensive and less predictable, while supplier lead times and raw material availability shift with little notice.

Companies are being forced to adapt quickly—relocating manufacturing, adjusting supplier relationships, and reevaluating market strategies. Internal demands for cost control, faster product development, and better coordination across global suppliers are also stocking up.

Surprisingly, many organizations still operate with fragmented systems and slow response times, widening the gap between strategy and execution. This increases the risk of costly delays, miscommunication, and supply disruptions. Even minor issues can cascade into major production setbacks without a connected approach.

Manufacturing Supply Chain Risks

Today’s supply chain risks go beyond fluctuating demand and shipping delays. Tariff escalations between major economies are driving up costs, forcing companies to reconfigure sourcing strategies at short notice. Recent U.S. duties on certain electronic components disrupted procurement timelines for high-tech manufacturers, delaying launches and increasing costs.

Environmental events add further uncertainty. Severe weather in Asia earlier this year halted critical semiconductor production, affecting multiple industries. Combined with shortages in metals like lithium and cobalt, manufacturers are under pressure to diversify suppliers, secure alternative materials, and improve forecasting accuracy.

To stay ahead of these disruptions, companies need systems that deliver real-time visibility and predictive insights—allowing them to identify risks early and adjust before production schedules are affected.

What is Supply Chain Risk Management?

Supply chain risk management helps manufacturers identify potential threats early, reduce their impact, and keep operations running smoothly. In a market where tariffs, export controls, and material shortages can hit without warning, preventing supply chain risks starts with accurate, connected data.

Rather than relying on static records and manual updates, manufacturers should benefit from a continuously updated flow of connected product data that links design intent to sourcing realities and manufacturing execution. This visibility enables teams to assess the downstream effects of changes, anticipate disruptions, and make informed adjustments for BOM management (bill of materials) before problems escalate.

A Digital Thread for Supply Chains

A true digital supply chain replaces manual, disconnected processes with a unified flow of accurate, real-time data. Every stage from design and procurement to manufacturing and delivery is linked, enabling teams to spot issues early, adjust instantly, and keep stakeholders aligned. Manufacturers benefit from shorter lead times, fewer errors, lower costs, and faster responses to shifting market conditions.

AI-powered PLM (product lifecycle management) software is the backbone for this connected ecosystem, creating a continuous digital thread that links product data, supplier information, and design changes. This ensures that when engineering updates a part, procurement sees it instantly, suppliers receive correct specifications, and production lines adjust without costly delays.

Modern features like 3D viewers, instant change orders, natural language search, and automated impact analysis allow teams to address risks before they escalate. By unifying engineering, sourcing, and manufacturing in a single environment, a digital thread reduces miscommunication, shortens lead times, and strengthens resilience, keeping supply chains competitive no matter how market conditions shift.

Taking Control of Supply Chain Risks

Before tariffs and geopolitical pressures tightened supply chains, we recognized the need for a system that could anticipate problems and respond without losing time or money. That’s why we built the first AI-native PLM platform to create a true digital thread for your supply chain, giving manufacturers a practical path to control risk before it controls them.

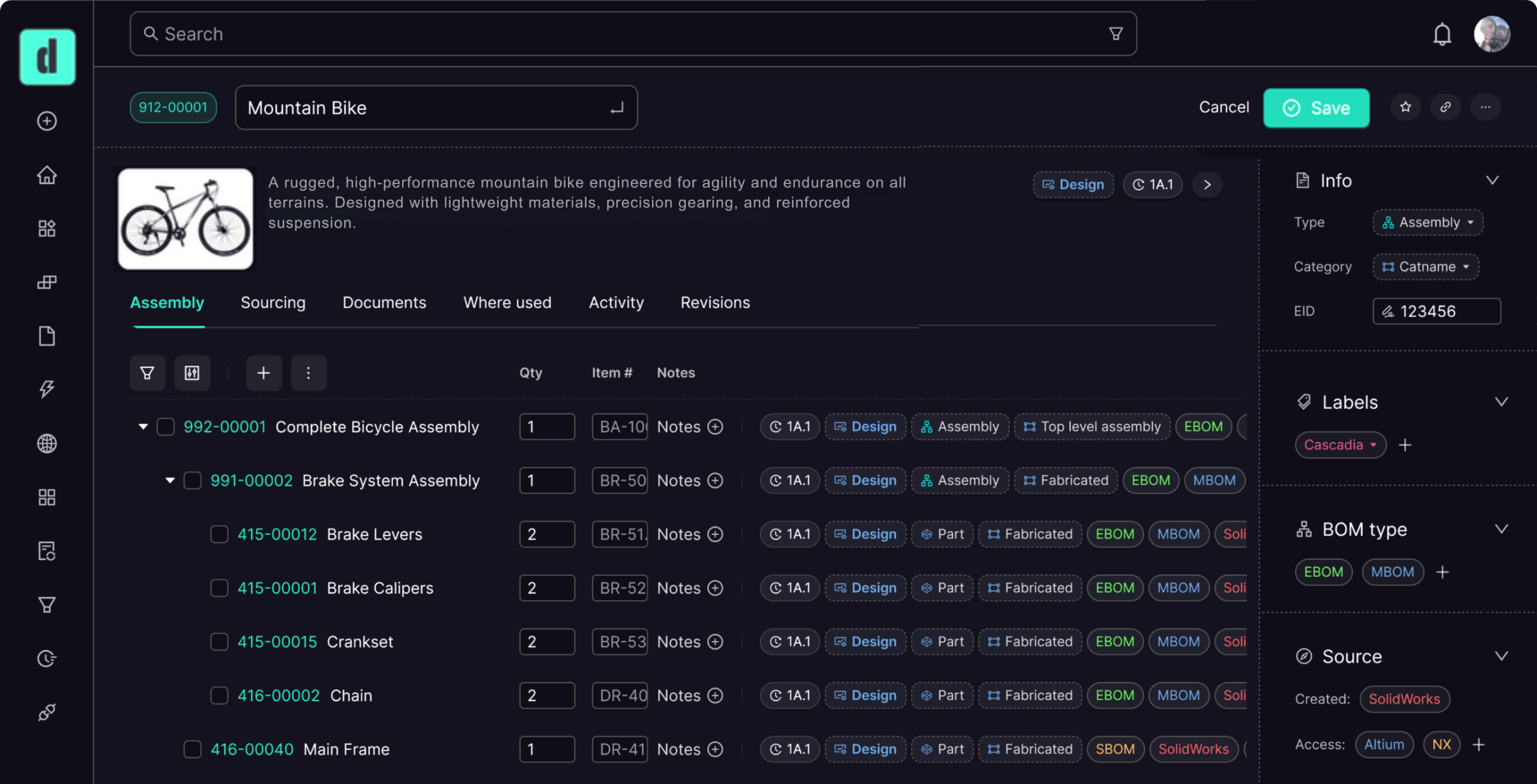

Duro Design unites BOM management, automated change order tracking, and unified supplier data in one platform, giving manufacturers complete visibility and control over their digital supply chain.

With real-time impact analysis and instant updates across engineering, procurement, and manufacturing, teams can catch risks before they escalate and adapt sourcing strategies in minutes instead of days.

Even small delays can mean millions of lost revenue in the global supply chain. With Duro Design, manufacturers gain the speed, clarity, and resilience to stay ahead. It’s the difference between hoping your supply chain holds together—and knowing it will.