TABLE OF CONTENTS

Product data management (PDM) software is a foundational tool for engineering teams managing complex design files, part revisions, and supplier documentation. As product development cycles compress and design collaboration becomes more distributed, the need for robust, efficient data control only increases.

More companies are adopting PDM software for version control, traceability, and secure file access. While PDM often works alongside PLM software (product lifecycle management), each plays a different role in managing product data and keeping development on track.

If your team relies on CAD tools like SolidWorks or Siemens NX, or you need alternatives to traditional on-prem PDM systems, this guide explains product data management, why it matters, and what to look for in modern PDM software.

What is PDM?

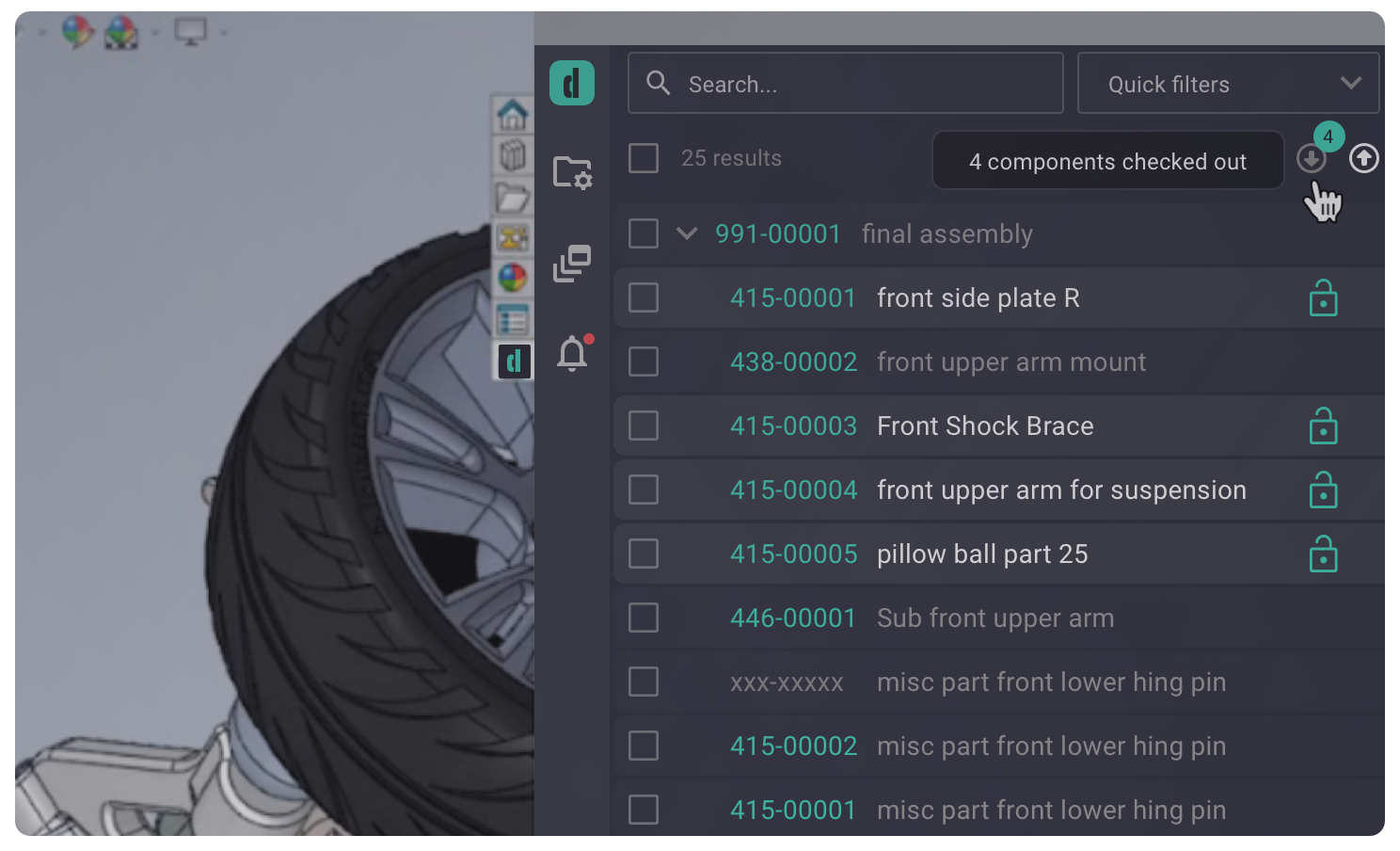

Product data management refers to the systems and processes that store, track, and manage design data, typically including CAD files, drawings, specs, and related documentation.

PDM software provides a single source of truth for product files, controls versions and revisions, records who made what change and when, prevents conflicting edits across team members, and securely stores everything in a centralized location.

Choosing the rice product data management system helps teams avoid version mix-ups and manual file handoffs, safeguarding design intent and traceability.

How PDM and PLM Work Together

While PDM software manages files and documentation, PLM software focuses on processes: engineering change orders, part approvals, BOM management, and product release workflows.

Think of it this way:

- PDM answers “What is this file and who touched it?”

- PLM answers “What’s the impact of this change and what happens next?”

Most modern companies need both. Without PDM, design data becomes scattered and error-prone, and without PLM, that data can’t flow cleanly through procurement, manufacturing, and compliance.

Choosing a PDM and PLM designed to integrate with each other solves all of these problems, allowing data to flow easily between systems.

Why PDM Belongs in Your Tech Stack

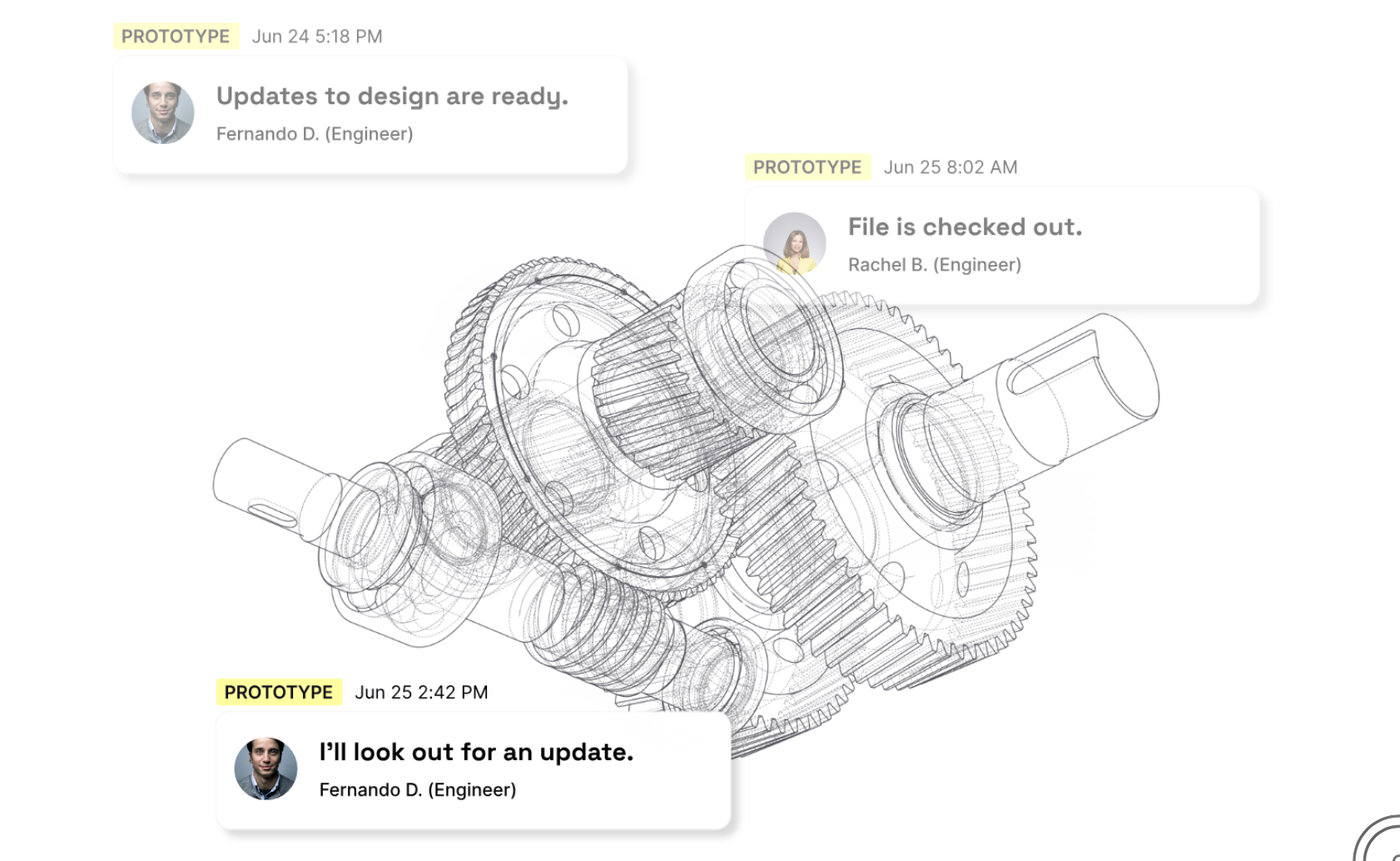

As teams grow and product development speeds up, relying on shared folders and manual file naming conventions starts to break down. It only takes a few engineers to edit the same design before version conflicts, missing revisions, and duplicate files cause problems.

Think overlapping changes, missing versions, and the inevitable question: “Which one is the latest?”The right product data management tool brings structure to that chaos.

PDM software gives everyone access to the right files and makes it easy to track who changed what without digging through email threads or folder histories. PDM also supports documentation standards, which companies in regulated industries need for compliance.

Product Data Management Features to Look for

When evaluating product data management software, focus on capabilities that make daily work easier, such as:

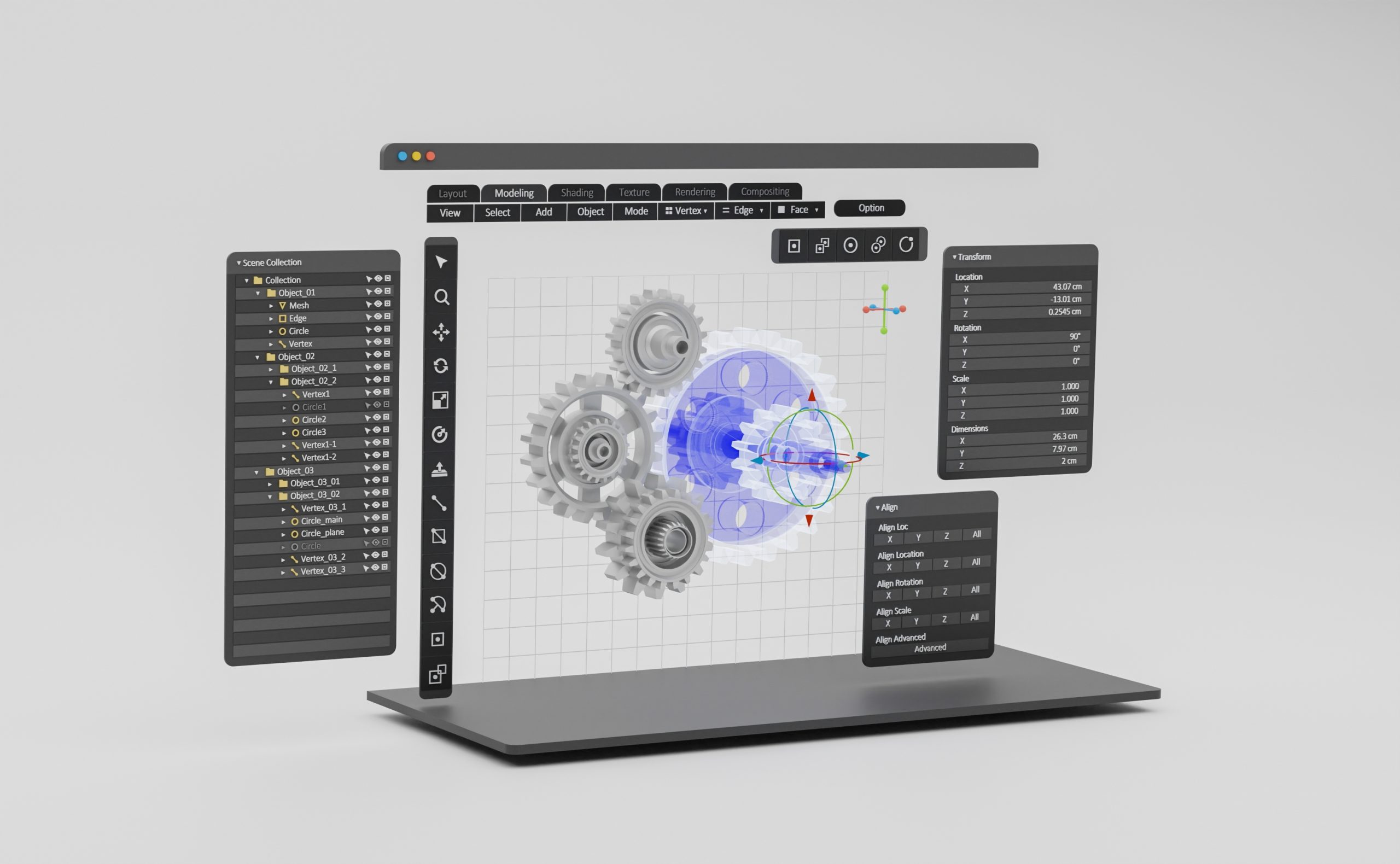

- CAD file integration: Ideally, your PDM system will connect directly to your CAD environment (SolidWorks, Altium, or Siemens NX), so files stay linked to their source.

- Version control: Strong version control should come standard, with revision tracking and safeguards to prevent accidental overwrites.

- Access controls: Access permissions allow you to define exactly who can view, edit, or release certain files.

- Searchable storage: Easy retrieval of drawings, specs, and other documents will save hours of time.

- Audit trails: The ability to see a clear record of every file change and approval.

If your team is working in SolidWorks and encountering limitations, it’s worth looking at SolidWorks PDM alternatives that provide more flexibility or the option for cloud-based storage and access.

Manage your Data with Modern PDM

For many, the move to modern product data management starts with replacing aging, on-premise systems or building a structure where none existed. Cloud-based PDM software has made that transition easier, removing the need for local servers and reducing IT overhead.

Your PDM should integrate directly with CAD tools, keep files versioned and traceable, and provide a centralized, searchable repository for design data. The best systems scale with your team, supporting both small groups and enterprise-level collaboration.

Selecting a PDM that’s simple to implement, integrates with your existing tools, and grows with your needs ensures your team can stay focused on designing, building, and delivering products without getting slowed down by file management challenges.

Schedule a quick demo with us to see how our PDM software can help.