TABLE OF CONTENTS

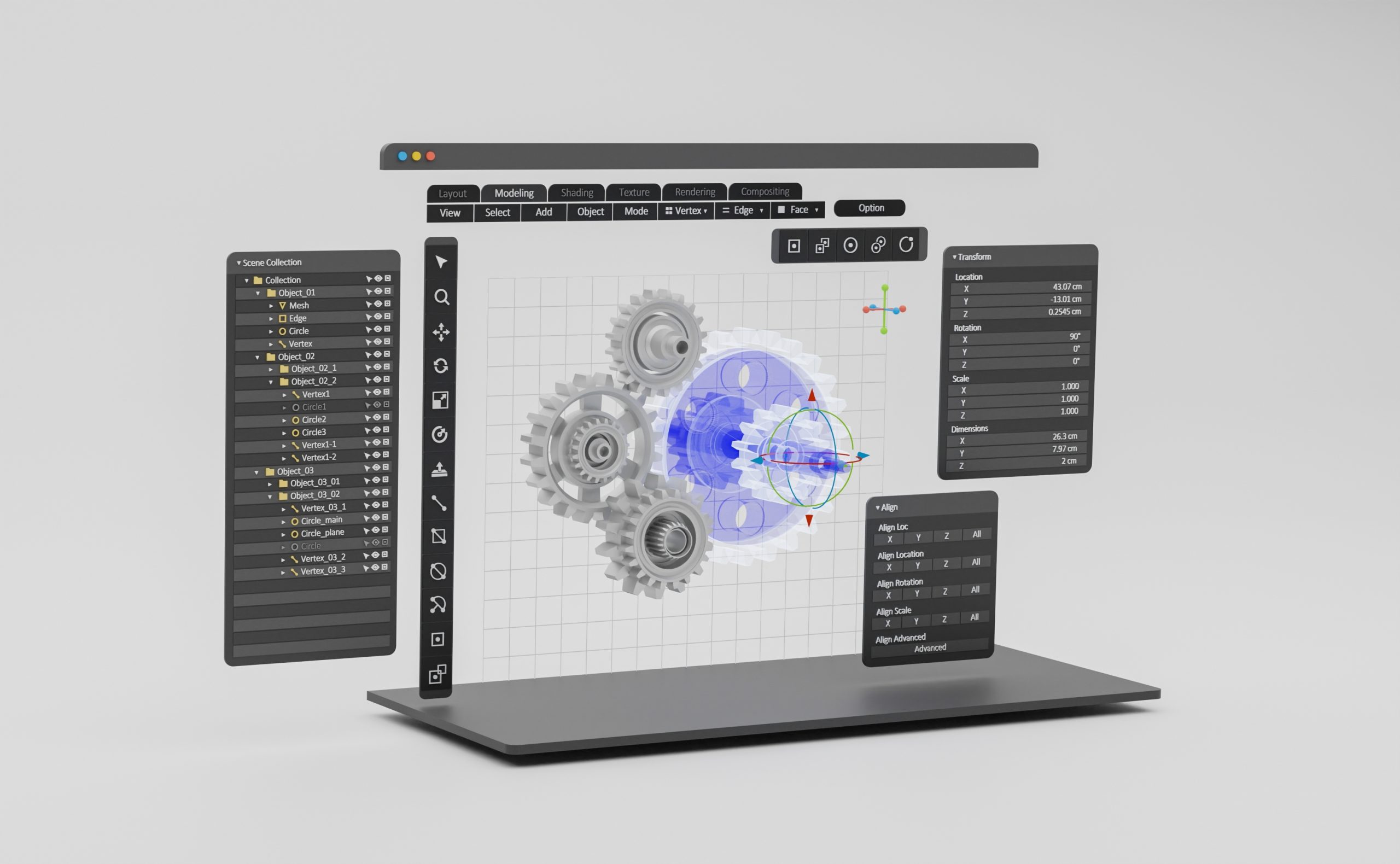

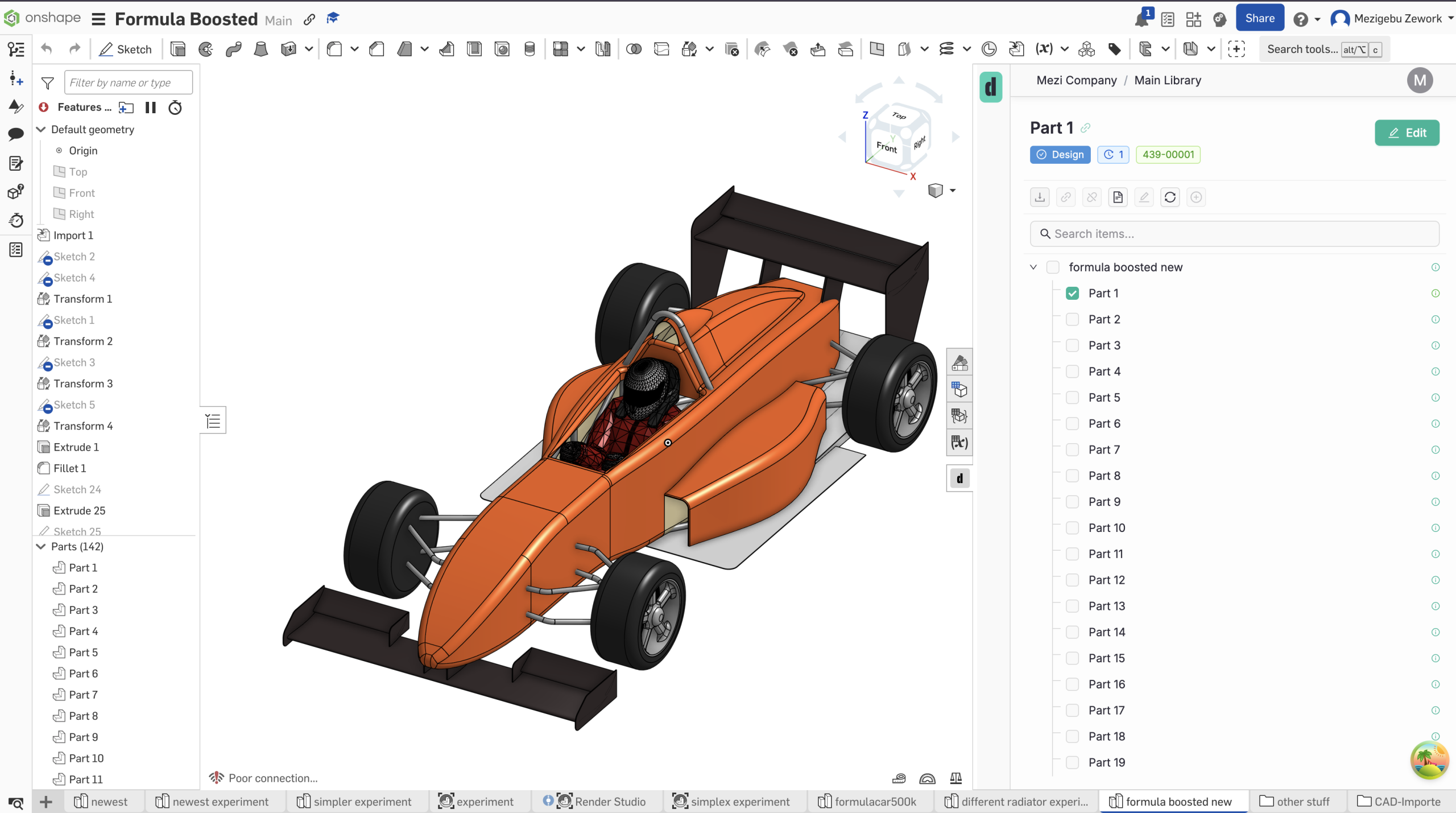

Onshape has changed how many hardware and engineering teams think about CAD. As the first major cloud-native CAD platform, Onshape gives engineers built-in version control and real-time collaboration without the headaches of local installs or PDM servers. For most companies, that’s a huge leap forward.

But, as products get more complex, PDM (product data management) alone isn’t enough. Managing CAD files is just one part of the equation. Teams also need a system to handle bills of materials (BOMs), supplier data, and engineering change orders (ECOs). That’s the role of Product Lifecycle Management (PLM) software.

Today, PLM software extends Onshape’s design capabilities into procurement, manufacturing, and operations. With PLM, engineering teams don’t just manage geometry—they connect design intent to the business processes that turn designs into shipped products.

Without PLM, companies often struggle with inaccurate BOM management, missed supplier updates, and costly rework downstream. So, the question for teams using Onshape is: Which PLM best fits a cloud-native CAD environment?

In this article, we’ll outline the best PLM platforms for Onshape, explain what makes each one stand out, and share the key factors to remember when selecting the right solution for your team.

Choosing a PLM for Onshape

The best PLM software should feel like a natural extension of Onshape, helping engineers, procurement, and manufacturing stay aligned without adding unnecessary friction. Here are the factors to weigh most heavily:

Native CAD–PLM Integration

Onshape users are accustomed to working in a browser-based, always-connected environment. A PLM platform should match that philosophy. Native integrations allow engineers to release designs, assign part numbers, and update product status directly from Onshape, without breaking their design flow. Solutions that rely on third-party connectors or manual exports introduce delays and create points of failure.

Closed-loop release process

Every design eventually has to move from CAD to a formal release process. The right PLM ensures that when a model is released in Onshape, it automatically enters structured workflows for approvals, ECOs, and downstream updates. This closed loop gives teams confidence that the BOMs and part data seen by procurement and manufacturing match the latest engineering record.

Bi-Directional Data Exchange

Onshape generates metadata—part names, materials, weights, and sourcing details—that needs to remain accurate as products evolve. A strong PLM pulls that data in from CAD and pushes updates back out, keeping both systems synchronized. Without this capability, teams risk working from incomplete or outdated information.

Ease of Adoption and Scalability

One of Onshape’s biggest selling points is how quickly teams can adopt it. PLM should be no different. Long enterprise deployments and heavy IT requirements can stall adoption. The best PLM platforms for Onshape are cloud-native, quick to configure, and flexible enough to grow with the business. They balance structure and agility, so small teams can get started fast while larger organizations can build out more complex processes over time.

Best PLM Tools for Onshape, Ranked

Several PLM systems integrate with Onshape to varying degrees—some natively, others through officially supported connectors. Below are the most widely used and proven options among Onshape users.

1) Duro

Duro was built from the ground up to integrate directly with Onshape. Unlike other PLM systems, Duro does not rely on third-party connectors or manual file exports. Engineers can manage part numbers and release workflows without leaving their design environment.

Duro’s Onshape integration fixes pain points that have plagued other systems. File exports are reliable, with synchronous generation for lightweight models (STL, Parasolid) and asynchronous processing with progress tracking for heavier files (STEP, drawings). Engineering change orders are approved in seconds and managed fully within Duro, eliminating conflicts if Onshape’s release management overlaps with PLM rules.

Duro’s bulk sync feature with source of truth selection lets teams update large volumes of data between Duro and Onshape with precise control. Engineers can search and filter components, define which system owns each field, and select properties to sync. The modular architecture delivers faster performance, completing operations for dozens of components in seconds.

For hardware teams, this translates into faster adoption, fewer errors, and greater confidence that procurement and manufacturing are always working from the latest design data. Because Duro is cloud-native, setup is quick and IT overhead is minimal—teams can be operational in days rather than months.

Why engineers choose Duro for Onshape:

- Embedded flyout panel in Onshape with real-time selection sync between CAD and PLM

- Change orders managed natively in Duro, not split across systems

- Reliable document generation with built-in progress tracking

- Bulk sync with a configurable source of truth and faster performance

- No middleware or disconnected tools; everything works in one cloud workflow

- Rapid setup with minimal IT involvement

2) Arena PLM

Arena is a cloud-native PLM platform from PTC that integrates tightly with Onshape through the Arena–Onshape Connection. This Arena PLM integration allows teams to sync BOMs, revisions, and ECOs directly from Onshape, automatically generating PDFs and STEP files for downstream use.

The arena PLM solution can work well for companies already invested in PTC’s ecosystem, as it can feel like a natural extension of Onshape, which connects design, product data, and manufacturing operations.

However, Arena’s depth and reliance on the larger PTC stack can make it feel heavier for smaller organizations. Hardware and engineering teams seeking quick configuration or agile workflows may find Arena PLM more complex than they need.

3) OpenBOM

OpenBOM focuses on flexible BOM management inside Onshape. Engineers can build and revise multi-level BOMs directly from CAD assemblies, sync data bi-directionally, and generate purchase orders and cost rollups without leaving their browser.

OpenBom is popular among early-stage hardware teams or companies prioritizing procurement visibility over full lifecycle control. OpenBOM’s design and App Store availability make adoption straightforward, while its integration keeps product data aligned with Onshape models.

However, OpenBOM is not a full PLM solution—it lacks built-in engineering change management and formal release workflows. It’s best suited as a BOM management solution or as a stepping stone toward a more robust PLM platform.

4) Aras Innovator

Aras Innovator is an enterprise-grade PLM solution that connects to Onshape through the XPLM connector. This setup allows CAD models and metadata to sync between systems, maintaining traceability and supporting existing PLM workflows.

Aras Innovator is a PLM software that is most attractive to companies that already run Aras as a solution and want to extend its reach into Onshape. It’s particularly relevant for teams building complex, regulated products that demand strict lifecycle governance.

Aras Innovator is powerful but heavy. The XPLM connector approach adds setup complexity and ongoing maintenance, which can be a hurdle compared to cloud-native PLM solutions explicitly designed for Onshape.

The Complete PLM for Onshape Users

While these PLM solutions bring unique strengths, Duro stands out as the most complete and purpose-built option for Onshape users. Its native integration eliminates connectors or manual exports, allowing engineers to release designs, manage ECOs, and keep BOMs accurate directly within their CAD environment.

Duro’s bulk sync feature with source of truth selection makes it easy to update large volumes of data between Duro and Onshape with precise control. Teams can filter components, define ownership for each field, and sync only the properties they need—ensuring procurement and manufacturing always work from the latest product data.

As the first AI-native PLM designed for modern hardware development, Duro uses built-in functionality—not just AI bolted on top—to streamline data synchronization, change management, and sourcing workflows. This approach helps teams move faster, reduce manual effort, and maintain complete confidence in their product record.

By combining Onshape’s cloud-native CAD environment with Duro’s AI-driven PLM, teams gain a unified system that extends from design through procurement and manufacturing—creating a true digital thread across the entire product lifecycle.